Broadcast Date: June 16, 2016 | 2:00 PM CDT

View the Webinar

Webinar Summary

Diacetyl is a pronounced flavor defect in beer, resulting primarily from improper fermentation control. But how do you measure diacetyl levels? What are acceptable specifications? What corrective action can you take? Featuring a panel of three industry experts from Lagunitas Brewing Co., Avery Brewing Co., and Stone Brewing Co., this webinar will cover a variety of options available to breweries for measuring diacetyl levels in beer, and how to use that data to control fermentation. Q&A session to follow speakers.

What you will take away:

- Diacetyl formation explained

- Measurement methods explained

- Tips and tricks to take your diacetyl measurement to the next level

- How to use the measurements to control diacetyl in your beer

Quality Mangers, Quality Technicians, or any brewer looking to expand their quality program, this webinar is for you!

About the Presenters

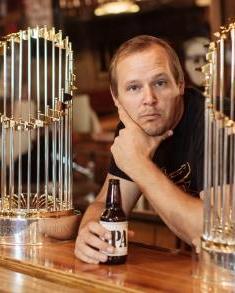

Bryan Donaldson

Lagunitas Brewing Co. |

Bryan Donaldson is the Consumer Quality Manager at the Lagunitas Brewing Company in Petaluma, CA. He received his Master of Science degree in Food Science and Technology at the University of California, Davis, where he researched hop aroma and completed a brewing internship at Anheuser-Busch. Prior to that he studied biochemistry at Santa Clara University. Bryan enjoys traveling and camping. He is currently the Vice President and technical chair for the Northern California district of the Master Brewers Association of the Americas. |

Dan Driscoll

Avery Brewing Co. |

Dan Driscoll is the Microbiologist and Yeast Prop Manager for Avery Brewing Co. in Boulder, CO, where he has worked for 5 years. Prior to the brewing industry, Dan worked extensively in molecular biology and microbiology labs around the country, including the CDC. He has a Masters in Applied Biotechnology from Oregon State University and Bachelors in Microbiology from Colorado State University. |

Rick Blankemeier

Stone Brewing Co. |

Rick Blankemeier left the world of natural gas process engineering for the realm of craft beer and hasn’t looked back. Rick helped establish the standard operating procedures for QA and QC at Stone Brewing Co. He has given presentations and seminars on quality assurance and lab testing at Master Brewers Association of the Americas annual meetings and Craft Brewers Conferences. Rick holds Bachelor’s and Master’s degrees in chemical engineering from the University of Colorado at Boulder. He currently works as the Quality Assurance Manager at Stone Brewing Co. |